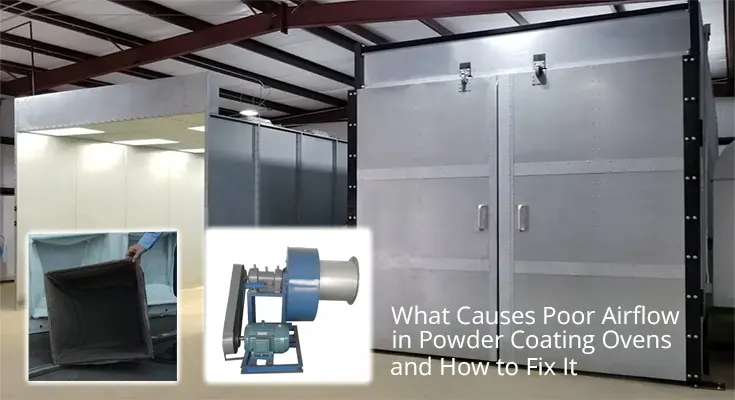

What Causes Poor Airflow in Powder Coating Ovens and How to Fix It

A powder coating oven relies on steady airflow to distribute heat evenly, ensuring a flawless finish. When airflow weakens, coatings may cure inconsistently, leading to defects, rework, and wasted materials. Understanding what disrupts airflow and how to fix it can prevent costly delays and maintain high-quality results.

Clogged Filters Restricting Airflow and Causing Uneven Heat Distribution

Filters play a critical role in keeping contaminants out of the oven’s airflow system. Over time, these filters trap dust, overspray, and other debris, reducing their ability to allow proper air movement. When filters become clogged, airflow weakens, causing uneven heat distribution inside the oven. This leads to inconsistent curing, with some parts overheating while others remain undercured.

Regular maintenance and timely filter replacements can resolve this issue before it affects production. Inspecting filters frequently and replacing them as needed ensures steady airflow. Some ovens have warning indicators for filter clogs, but manual …

What Causes Poor Airflow in Powder Coating Ovens and How to Fix It Continue Reading >>>